*This is a Washington State average for this occupation. Wage rates vary by employer, industry, experience and location.

What is a Production Machine Operator?

Machine operators in production environments are skilled professionals responsible for operating, monitoring, and maintaining machinery used to manufacture goods.

These operators work across various industries, including automotive, aerospace, food processing, and consumer goods. They ensure machinery functions efficiently, maintain high-quality standards, and minimize downtime.

Key responsibilities include:

- Setup and Calibration: Preparing machines for production by setting controls, installing parts, and conducting test runs.

- Operation and Monitoring: Running machines to produce parts or products while observing performance to ensure quality and efficiency.

- Troubleshooting and Maintenance: Identifying and addressing issues with machinery, performing minor repairs, and collaborating with maintenance teams for major fixes.

- Quality Control: Inspecting products for defects and adhering to production specifications and safety standards.

- Documentation and Reporting: Logging production data, maintaining maintenance records, and reporting equipment issues to supervisors.

Machine operators often work in fast-paced environments where teamwork, attention to detail, and a commitment to safety are crucial.

What are the Benefits of Becoming a Production Machine Operator?

Becoming a production machine operator offers a stable and rewarding career path with significant opportunities for growth.

With the increasing demand for skilled workers in industries like food processing, automotive, aerospace, and manufacturing, this role provides strong job security and competitive wages. Many operators enjoy hands-on work, where they oversee and maintain machinery, troubleshoot issues, and ensure product quality.

A Production Machine Operator is an entry-level apprenticeship occupation that develops foundational manufacturing, machining, and maintenance skills.

Upon completion of a Production Machine Operator apprenticeship, you can move onto more advanced occupations such as Machinist or a Maintenance Technician.

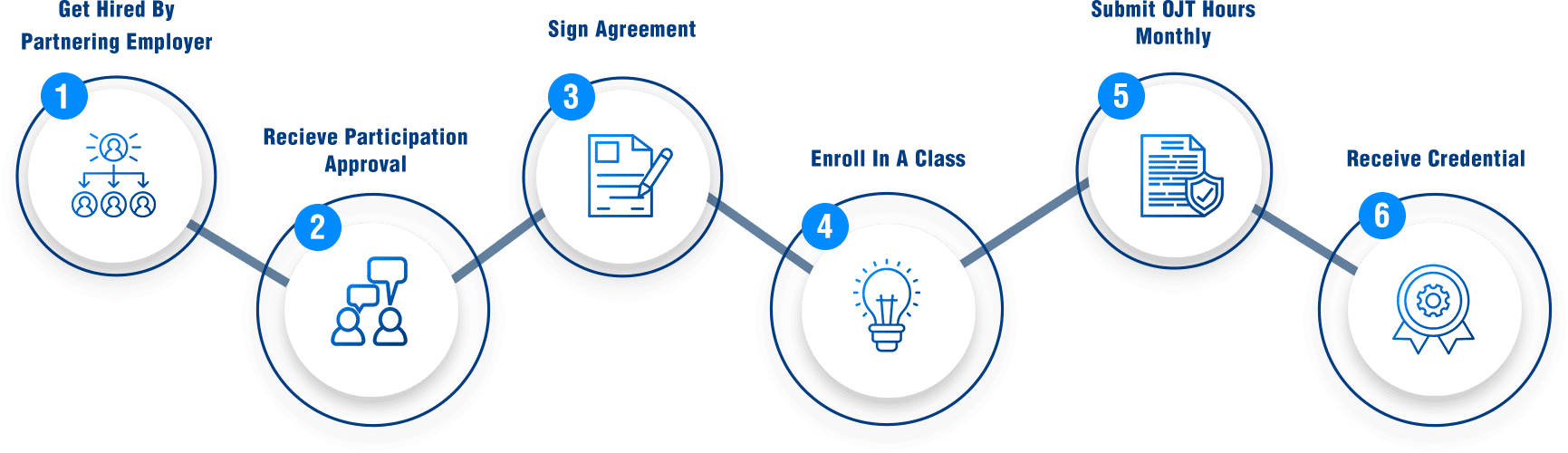

Steps to Becoming an Apprentice

6 Steps to Becoming an Apprentice

Get Hired by a Participating Employer AJAC Partners With

Receive Participation Approval from Your Employer

Sign an Apprenticeship Agreement with AJAC

Enroll in AJAC’s Apprenticeship Classes Each Quarter

Log and Submit Your OJT Hours Monthly

Receive a Nationally-Recognized Journey-Level Certification from L&I

How Much Can I Earn?

Where Will I Work?

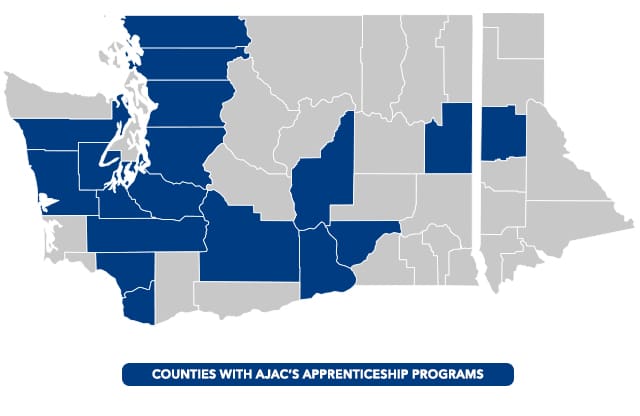

AJAC has partnered with 300+ advanced manufacturers to provide supervised, structured, paid on-the-job training.

AJAC apprentices can only work for companies that agree to hire them and place them into the program.

Each company has their own methodology for who they select as an apprentice.

Where Are Classes Held?

Classes are held one night a week, typically on a Tuesday, Wednesday, or Thursday from 5:00 pm to 9:00 pm.

AJAC’s apprenticeships classes are structured for both online learning or in-person learning. Depending on the specific class you are taking, you may be required to complete it online or in-person.

In-person classes are held either a local community/technical college, high school, or skills center.

There may be an option for companies to participate in AJAC’s cohort model for this occupation.

Apprenticeship Classes

Production Machine Operator apprentices take six college-level classes. Each class consists of 50 hours of lecture and/or practical application. Upon completion of each class, apprentices will receive 5 college credits.

As a registered apprentice, you automatically receive 50% reduced tuition. Over half of AJAC’s partnering employers elect to pay for their apprentice’s tuition, making the entire apprenticeship free-of-cost.

Currently, each class costs $380 out-of-pocket.

This is the first of two courses that explores the foundational principles and skills of industrial machine maintenance as it relates to a machine operator. Apprentices learn predictive and preventative maintenance and troubleshooting strategies for machine repair.

This is the second of two courses that explores the foundational principles and skills of industrial machine maintenance as it relates to the machine operators. Apprentices learn about mechanical rigging and installation, including safety, installation, and ways to perform lifts.

In this course, apprentices develop an understanding of the functions of a Quality Assurance (QA) system. They identify the elements of QA systems and how they support safe food manufacturing processing. They learn the purpose of food safety and quality practices and strategies.

This course introduces apprentices to metallurgy, material properties, and the processes used to manipulate metals. They will study the composition and characteristics of steel, stainless steel, cast iron, aluminum, and brass while exploring manufacturing techniques like machining, casting, forging, and heat treatment. Hands-on projects and modern inspection methods, such as hardness testing and non-destructive testing, provide practical experience in material testing and identification.

Learn to read and interpret engineering drawings and schematics, as well as practice basic drafting. Drawings studied in this class will come both from the text and from industry, and will include machining, fabrication, assemblies, and fluid power systems (only for Automation/Maintenance program).

In this course, students will be able to relate LEAN Six Sigma concepts to production objectives. They will identify waste within the value stream and demonstrate the ability to effectively analyze and present data to co-workers and stakeholders. They will define and apply team leadership tools to aid in process improvement. Students will collect and process customer or internal stakeholder input/requirements and identify key metrics for measuring success. Students will define the DMAIC process and effectively use tools and concepts associated with each phase of the DMAIC process. Finally, they’ll employ Lean Six Sigma skills in process improvement projects.

On-the-Job Training Competencies

The table below is a schedule of tasks and hours designed as a guide. The 3,000 hours will be completed over the course of the apprenticeship. The apprentice shall be instructed and trained in all operations and methods customarily used on the various machines. Each company will adhere to the schedule as closely as facilities will permit in order to provide the apprentice with well-rounded experience and practice on all relevant equipment and processes in the shop.

| OJT Competency | Approx. OJT Hours |

|---|---|

| Preventative & Predicative Machine Maintenance | 300 |

| Manufacturing Basics & Safety | 500 |

| Quality Assurance Basics | 800 |

| Manufacturing Equipment Setup & Production Processes | 1,400 |

| TOTAL HOURS | 3,000 |

Launch Your Career Today!

Submit your information using the link below. After we receive your information, an AJAC representative will contact you for next steps. Please note, this is not an official application to become an apprentice. After a partnering employer agrees to enroll you in the program, you will officially apply and enroll at that time.